Total Organic Carbon analysis is one of the preferred approaches to Cleaning Validation, as it offers a highly sensitive, non-specific measurement of all organic residues present in a swab or rinse extract. Because TOC captures total organic loading rather than a single analyte, it is particularly efficient when multiple potential residues may be present on equipment surfaces.

Key advantages of TOC for cleaning validation include:

- Universal detection of organic compounds, including APIs, excipients, detergents, process aids and degradation products

- Low detection limits suitable for high-purity systems and stringent acceptance criteria

- Minimal method development, in contrast to substance-specific chromatographic techniques

- Rapid sample throughput, supporting both extensive validation exercises and routine monitoring

- Strong regulatory acceptance across major pharmacopoeias and industry guidance documents

By using TOC as the primary screening tool, manufacturers can rapidly confirm effective cleaning or identify when further investigation using targeted analytical methods is required.

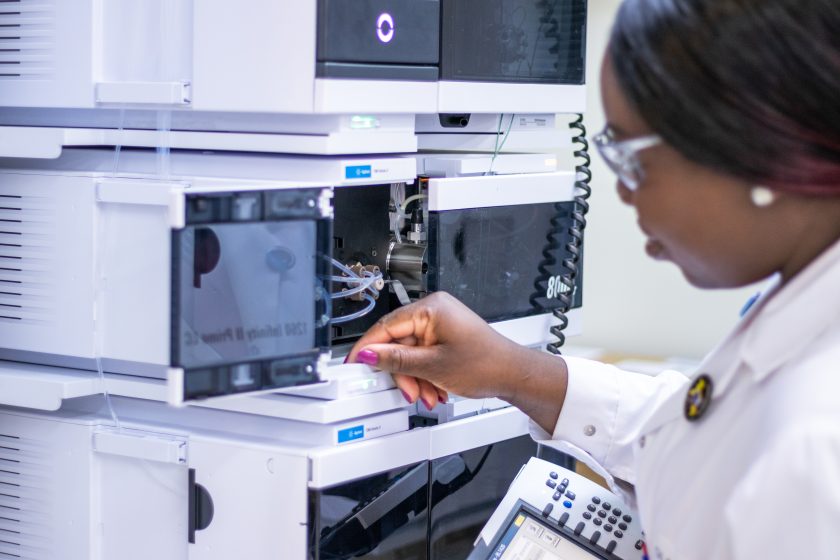

Integration with Chromatographic Methods

While TOC is the most efficient first-line technique for cleaning validation, there are circumstances where quantification of specific residues is necessary. In such cases, Butterworth Laboratories can apply:

- HPLC for active ingredients and excipients

- GC for volatile or semi-volatile residues

- IC for ionic species from detergents or cleaning agents

These targeted techniques are typically used only when TOC results indicate that further characterisation is required, allowing a stepwise, cost-effective, scientifically justified approach.

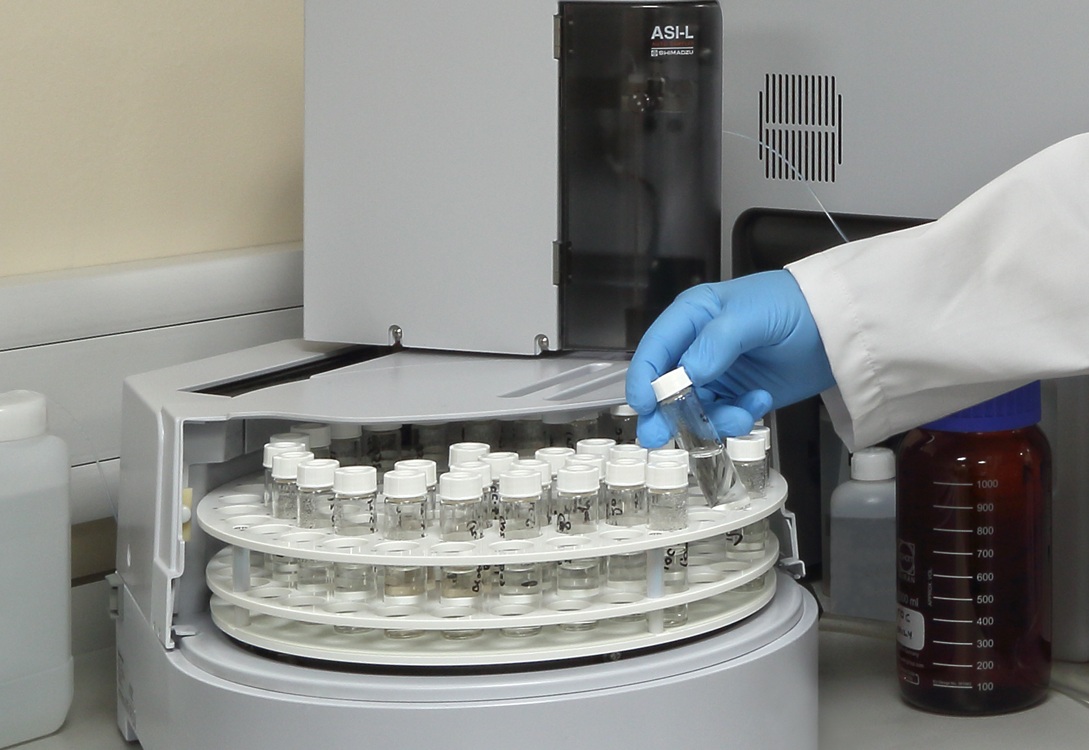

Sampling for Cleaning Validation

Reliable cleaning validation begins with appropriate sampling. We support all common sampling strategies, including:

- Swab sampling for hard-to-reach or low-volume surfaces

- Rinse sampling for large surface areas or internal systems

- Composite swabbing where multiple locations must be assessed efficiently

Swab types, extraction solvents, sample handling and recovery studies need to be carefully considered to ensure that TOC results accurately reflect actual residue levels.

Routine Monitoring and Requalification

Once a cleaning procedure has been validated, periodic testing is required to maintain compliance. TOC is ideally suited for routine verification due to its speed, sensitivity, and minimal preparation requirements. Regular TOC monitoring provides an early indication of changes in equipment cleanliness or the performance of the cleaning process.

Frequently Asked Questions

TOC testing is used to detect and quantify organic contaminants in water or other samples. It’s widely used across regulated industries because it provides a fast, reliable indication of cleanliness, contamination, or water quality.

TOC testing is used in the pharmaceutical and biotech industries to detect and quantify organic contaminants in water and on equipment surfaces. It ensures that critical systems, such as Purified Water (PW), Water for Injection (WFI), and Clean-in-Place (CIP) processes, are free from residual organic material. TOC testing supports regulatory compliance with EP, USP, and JP requirements, verifies equipment cleaning, monitors water systems in real time, and helps maintain product purity and patient safety.

– Detects all organic compounds, including APIs, excipients, detergents, and degradation products

– Very low detection limits, suitable for high-purity systems

– Minimal method development, saving time and resources

– Rapid sample throughput for large validation programs or routine monitoring

– Strong regulatory acceptance across major pharmacopoeias and industry guidance

Chromatographic methods are used only when TOC results indicate that specific residue quantification or identification is required. They are ideal for:

– HPLC : active ingredients and excipients

– GC : volatile or semi-volatile residues

– IC : ionic residues from detergents or cleaning agents

This stepwise approach ensures a cost-effective, scientifically justified workflow.

Major pharmacopoeias and industry guidance widely recognise TOC as an acceptable non-specific screening technique for cleaning validation. It allows manufacturers to demonstrate compliance with stringent residue limits and monitoring requirements.