For over 40 years, Butterworth Laboratories has provided independent, contract analytical services to the global pharmaceutical and related industries.

Empowering Precision, Elevating Sustainability with Gas Generation Technology at Butterworth Laboratories

4 July 2025

About a year ago, Butterworth Laboratories acquired three new Gas Generators. Our laboratory managers had long considered this decision, which was driven by the numerous advantages gas generators offer over traditional gas cylinders. Below is a summary of our experience with these new systems so far.

Precision Zero Air Generator

The Precision Zero Air generator range generates high-purity air, achieving levels of less than 50ppb Methane, using a catalyst chamber that eliminates methane via catalytic oxidation.

Precision Hydrogen Generator

The Precision Hydrogen Trace generators use a high-quality Proton Exchange Membrane (PEM) cell to electrolyse water to produce 99.99999% hydrogen and a regenerative Pressure Swing Adsorption (PSA) dryer to remove residual moisture from the gas.

Precision Nitrogen Generator

The Precision Nitrogen generator produces UHP Nitrogen at 99.9995% purity using Pressure Swing Adsorption (PSA) to remove oxygen from compressed air. This process is completely regenerative and produces nitrogen gas with a dew point of less than -70°C.

The Nitrogen and Hydrogen generated by the gas generators serve a dual purpose: they provide fuel for the Flame Ionisation Detectors (FID) of our Shimadzu Nexis 2030 and the associated Headspace HS20NX while simultaneously functioning as carrier gases. This has resulted in a notable enhancement in the performance of our chromatography systems.

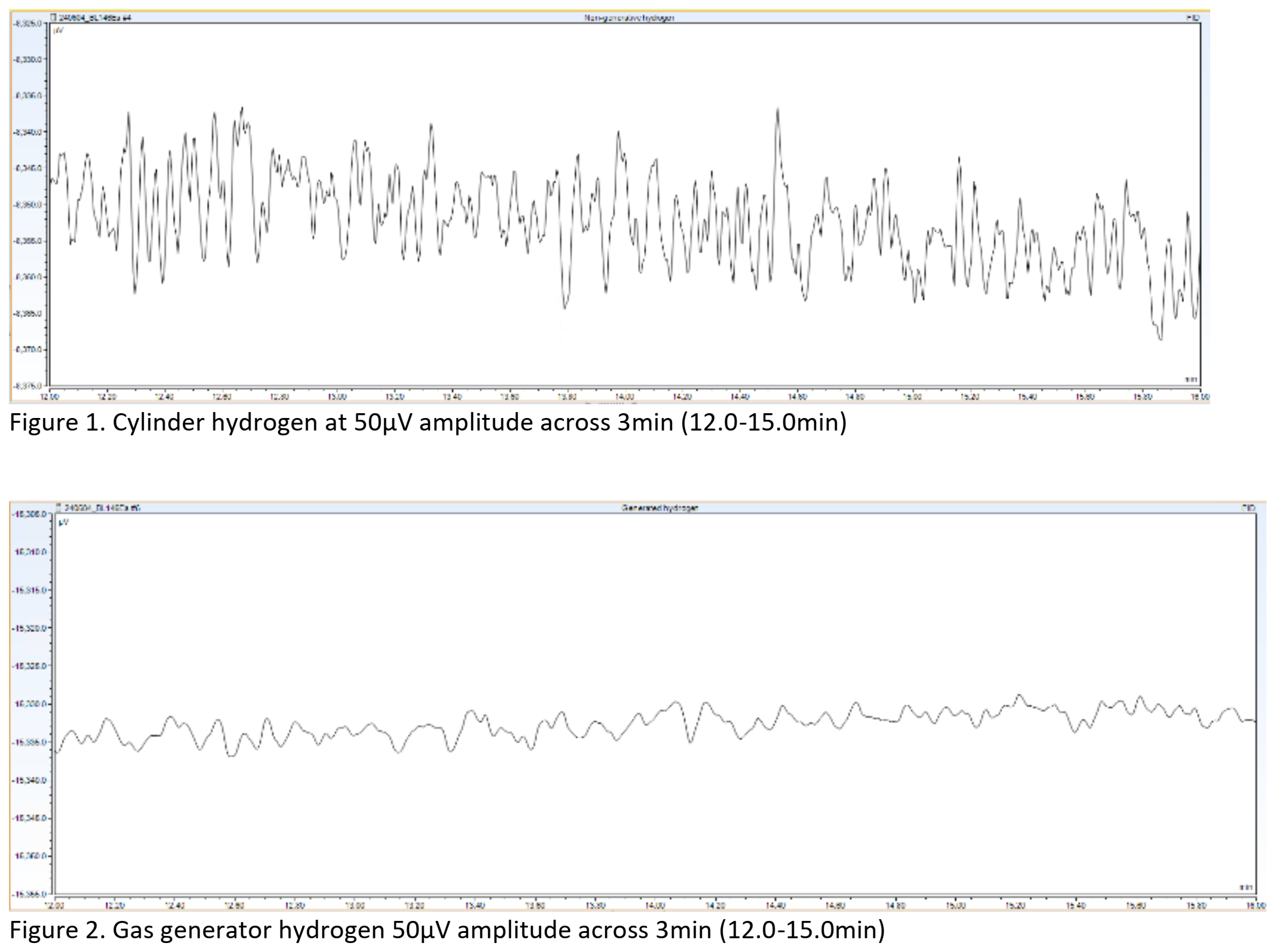

Specifically, implementing these gas generators has led to a significant improvement in the recorded baseline of our detectors, as demonstrated by the chromatograms below. Both data sets were obtained using the same instrument, the same GC column, and the same method, ensuring a fair comparison. In Figure 1, the baseline is shown when the FID was fueled using traditional gas cylinders. In contrast, Figure 2 illustrates the baseline after switching to gas generated in-house by the new system.

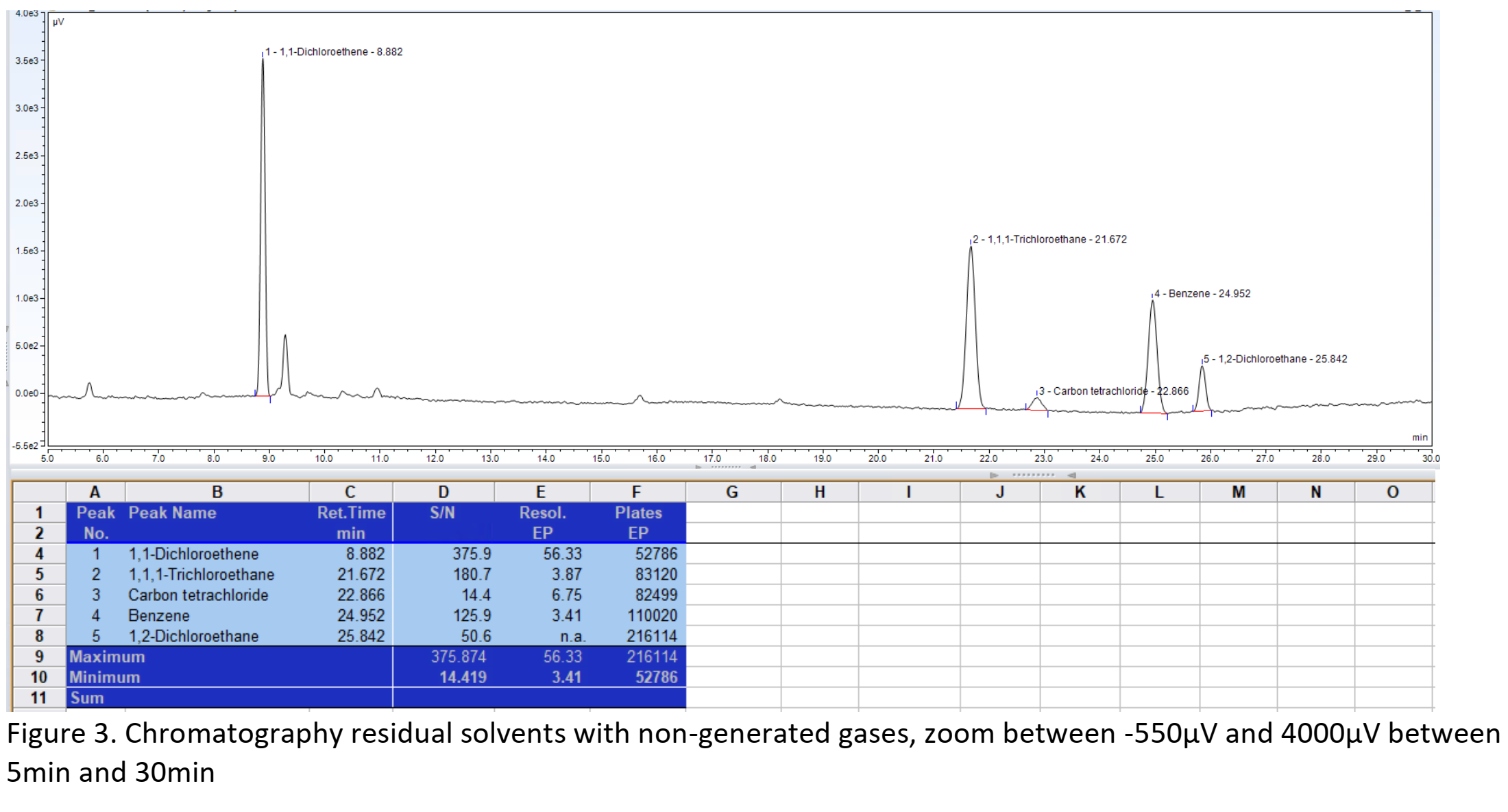

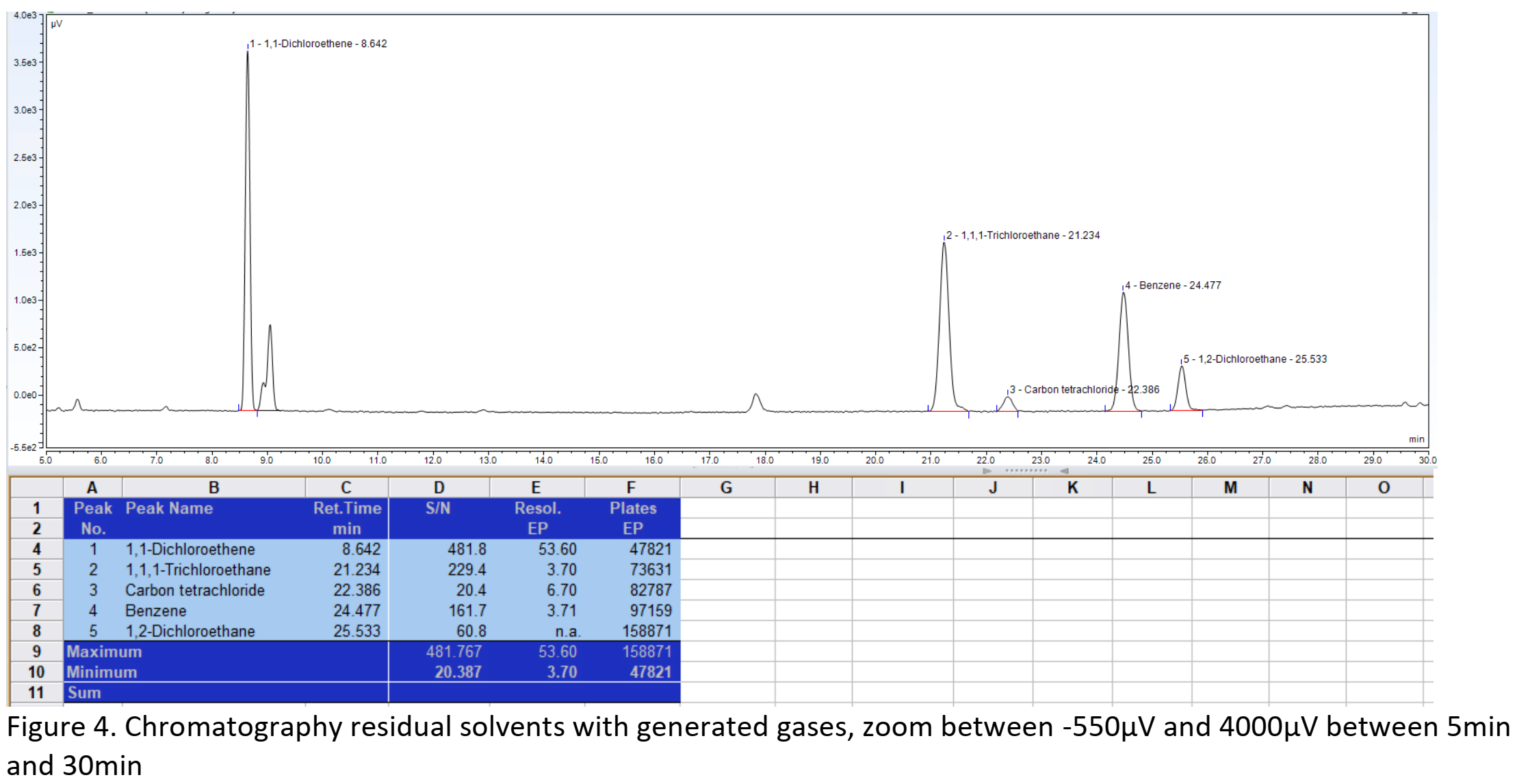

Further analysis compared the chromatography results obtained before (Figure 3) and after (Figure 4) the installation of the gas generators. The improvement in baseline stability has directly contributed to a significant increase in sensitivity, with the signal-to-noise ratio improving by 20% to 30%.

Beyond the enhancements in analytical performance, gas generators offer several operational advantages. The reliance on gas cylinders has been drastically reduced, leading to fewer cylinder deliveries and a consequent decrease in the carbon footprint associated with fossil fuel consumption.

Additionally, the physical and carbon footprint of high-pressure gas cylinders on site has been minimised. The generators continuously provide a stable supply of high-quality gas tailored to the specific requirements of our Gas Chromatography instruments, ensuring optimal performance with a reduced environmental impact.

Conclusion

The entire process was remarkably smooth, including purchasing, installing, and qualifying the gas generators. The transition was seamlessly integrated into our operations, with analysts and managers expressing high satisfaction with the setup.

The observed benefits reinforced our decision, demonstrating that gas generators are a reliable and efficient alternative to gas cylinders. They are also a strategic enhancement to our laboratory’s capabilities and our aim to become more sustainable.

Come and talk to us about our experiences and discover the ways we may be able to assist you with making your gas chromatography more sustainable.

Artur Gascon

Team Leader – Gas Chromatography