For over 40 years, Butterworth Laboratories has provided independent, contract analytical services to the global pharmaceutical and related industries.

No More Blue Fingers – Butterworth Pass the Amino Acid Test

2 September 2022

The problem with amino acid analysis has always been that while ion-exchange liquid chromatography is the preferred process to separate free amino acids, the resolved sample components can’t be detected with the required sensitivity using UV or other common universal liquid chromatography detectors. Amino acid analysers, therefore, mix the eluent from the analytical column with Ninhydrin which is then heated to give derivatives that absorb UV radiation. Primary amines give blue-violet derivatives which are measured with the absorbance at 570 nm. Because proline and hydroxyproline produce yellow-red derivatives, they are measured with absorbance at 440 nm. The overall procedure is referred to as post-column Ninhydrin derivatisation and complies with PhEur 2.2.56. The elution of sample components is based on the pH of the eluent which is increased as the analysis progresses.

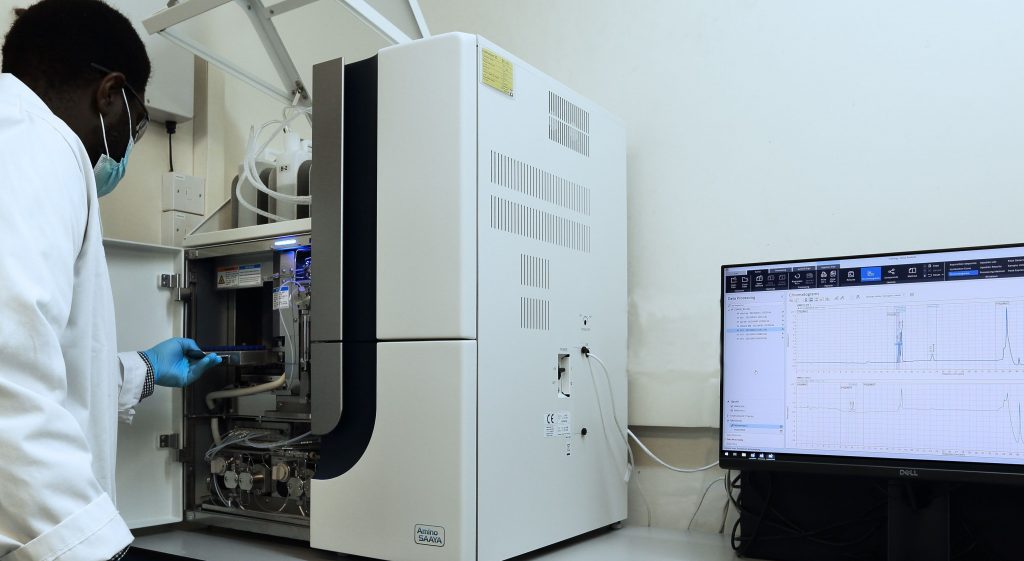

It is now 12 stress-free months since Butterworth retired its in-house configured amino acid analyser following the qualification of our new Hitachi LA8080 High-Speed Amino Acid Analyser. This system is now providing many benefits for both Butterworth and our clients.

Amino acid monographs in PhEur require determination of ammonia in addition to other amino acid contaminants. Following the purchase of the LA8080, which excludes non-sample-related ammonia from the system, amino acid impurities and ammonia are quantified with a single method. This has resulted in a 40% cost saving for clients compared to the two methods we were previously employing.

The run time for each injection has been reduced from 120 to 60 min. This reduces reporting time for sample batches.

The new system is more compact and reduces bench requirements by 35%.

The amount of system training required by analysts has been reduced by 50%.

The system uses onboard, 2 component, Ninhydrin reagent mixing. Unlike many other single component reagents, these do not require refrigeration before use and have extended shelf life.

The previous instrument generally with time, saw increased back pressure from the analytical column but more markedly from the Ninhydrin reaction coil due to scaling of baked reagent. This increase in system backpressure gave rise to the leaking of Ninhydrin reagent and even when gloves were used, it was nearly always the case when unblocking the system, that at some point the leakage would result in blue fingers! These problems are no longer encountered since both the analytical column and Ninhydrin reactor are now separately flushed and regenerated after each sample injection. This has greatly reduced instrument downtime and unexpected reporting delay.